SC Johnson is a fifth-generation family company built on the spirit of our people.

We have been leading with purpose for over 130 years, building trusted brands that win the hearts and minds of consumers – such as Raid®, Glade®, Ziploc®, Mr Muscle® and more, in virtually every country around the world. Together, we’re at work for a more sustainable, healthier, transparent world with more opportunity for all. Join our winning team driven to make an impact and help us write the next chapter in the SCJ story.

Explore Career Opportunities at SC Johnson

Corporate

Browse opportunities across all functions from Sales and Marketing to Supply Chain, Research, Development & Engineering to Human Resources and more.

Search Jobs

Manufacturing

Explore the roles that bring our products to life for consumers at manufacturing facilities around the globe.

Search Jobs

Lifestyle Brands

Discover careers within our house of like-minded brands including Method®, Mrs. Meyer's Clean Day®, babyganics® and Ecover®.

Search Jobs

Professional

Discover careers within our division providing solutions to healthcare, industrial and institutional markets across the world.

Search Jobs

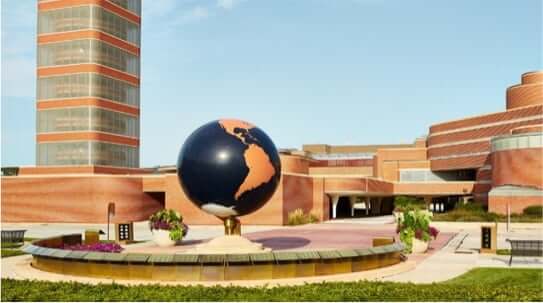

OUR GLOBAL LOCATIONS

Where will you make an impact?

Our 13,000 team members support the business from offices and manufacturing facilities across more than 70 countries. Discover features of our largest operations and search opportunities by region or country.

Explore Our Locations